Bus Bar Manufacturing Services – Precision. Speed. Turnkey Solutions

From plating to precision manufacturing — your custom bus bars, ready to install, from one trusted source.

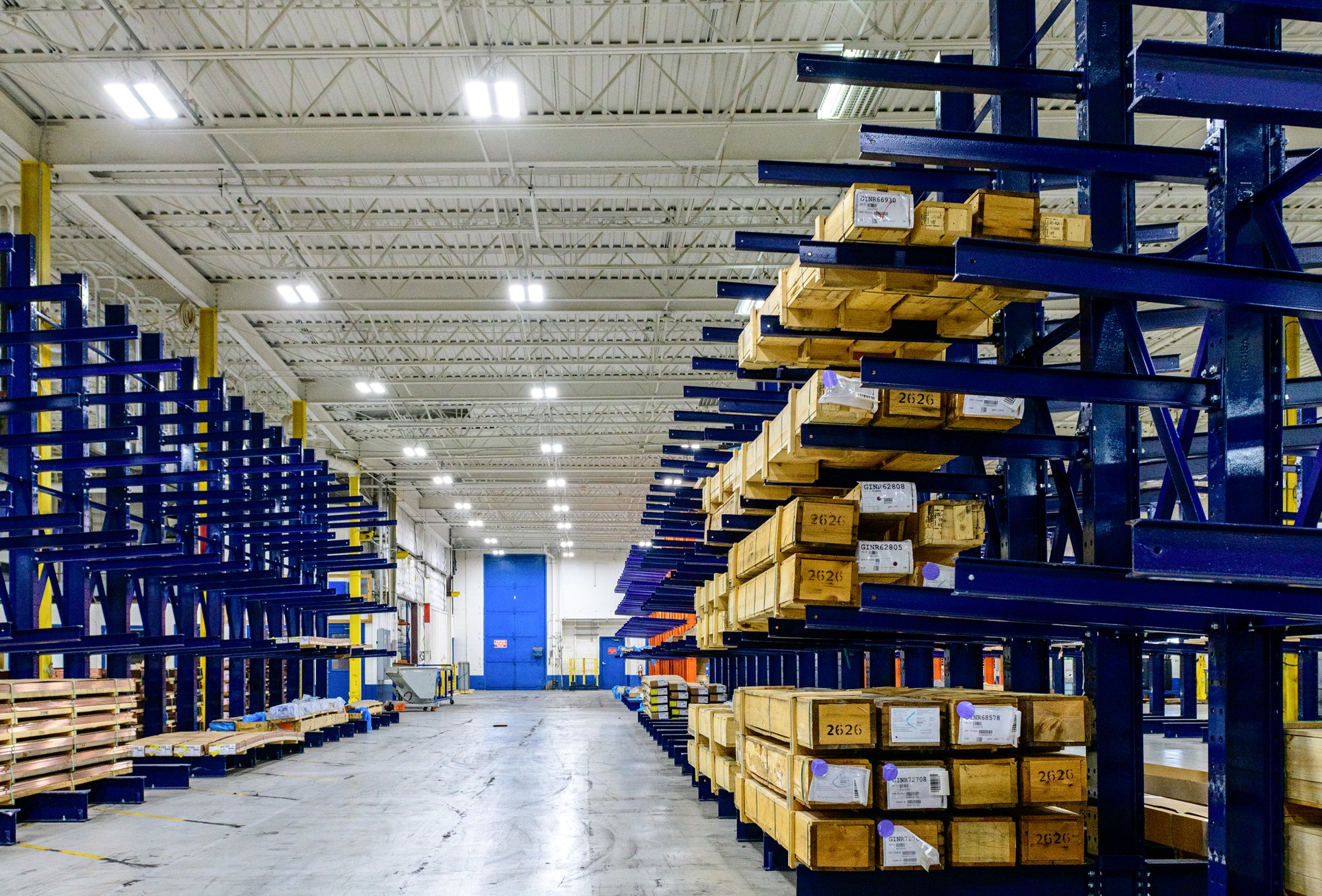

With our end-to-end bus bar capabilities, S+S Industries is the perfect partner for data centers and switchgear manufacturers. We plate and coat for improved conductivity and rust prevention, and our manufacturing division punches, bends, stamps, and delivers ready-to-install parts.

Eliminate the hassle of multiple vendors and long lead times. Partner with S+S Industries for premium, made-to-order bus bars.

Complete Bus Bar Manufacturing, Start to Finish

Whatever configuration your bus bars demand, we offer custom punching, bending, and stamping to exact specifications. Our precision manufacturing delivers bus bars for mission-critical electrical infrastructure—optimized for ventilation, secure component and accessory attachment, tight-tolerance fit, easy identification, and more.

We’re able to work from the specs you provide or to collaborate to optimize designs for availability and performance.

For added performance, we can integrate our proprietary Hyper Plate and Power Plate processes into the production for high-performing, corrosion-resistant bus bars.

Our Manufacturing Customers

Data Center Leaders

As data centers scale rapidly, S+S is the partner that helps you meet demand—end to end. We provide data center operators with hyperscale-grade bus bars that can support high-current, high-reliability applications, from AI model training to real-time global services.

Switchgear & Power System Manufacturers

OEMs and Tier 1s alike trust S+S to meet their bus bar needs in assembling durable, efficient switchgear systems. Our bars can be put to work in switchgear of all voltage classes—low, medium, and high.

If your switchgear incorporates panelboards or control cabinets, our bus bars can be used in modular arrays to simplify wiring, improve airflow, and enhance safety.

U.S.-Based Infrastructure Projects

S+S bus bars leave our plant bound for domestic infrastructure projects all over the country. These made-in-America products help reduce reliance on overseas production and help make energy efficiency possible.

Why Choose S+S Industries for Bus Bar Manufacturing?

Turnkey Process – From Plating to Production

Consolidating all your bus bar services with S+S delivers measurable value. By handling both plating and manufacturing in-house, we reduce complexity and can shorten your project timeline by weeks.

Engineering Support

Value-added engineering and consultation with our experts helps you optimize your designs for the best performance and longevity. They can also help you adjust your specs based on material availability and cost efficiency.

Trusted by Industry Giants

We plate and manufacture parts for some of the world’s most demanding applications, including mission-critical sectors where failure is not an option.

Scalable Production

Thanks to our extensive suite of fabrication equipment, we can ramp production from prototypes to large-scale runs on short notice. We are extremely proud of our state-of-the-art CNC machinery by globally recognized manufacturers EHRT, Rittal Automation Systems and more, including the FlexPunch and the EB 40 Professional E bending machine.

The S+S Bus Bar Manufacturing Journey, from Design to Delivery

Consultation & Spec Review

We ensure we understand your requirements and identify opportunities for improvements.

Material Selection

We make recommendations for conductivity, durability, cost and availability.

Plating

We protect your parts with S+S signature finishing solutions Hyper Plate or Power Plate.

Manufacturing

We punch, bend, and/or stamp to your specifications.

Quality Control & Delivery

We conduct a final inspection, package products, and ship on time.

Contact S+S Industries for a Quote

If your business involves bus bars, it’s time to start manufacturing wins. Let S+S give you an edge through better lead times and our ability to handle urgent projects.