Comprehensive Plating & Coating Services

We are your single source for industrial equipment solutions, from plating and coating metal parts with a wide variety of materials, to warehousing of your raw materials and assembly of finished products before delivery to your sites.

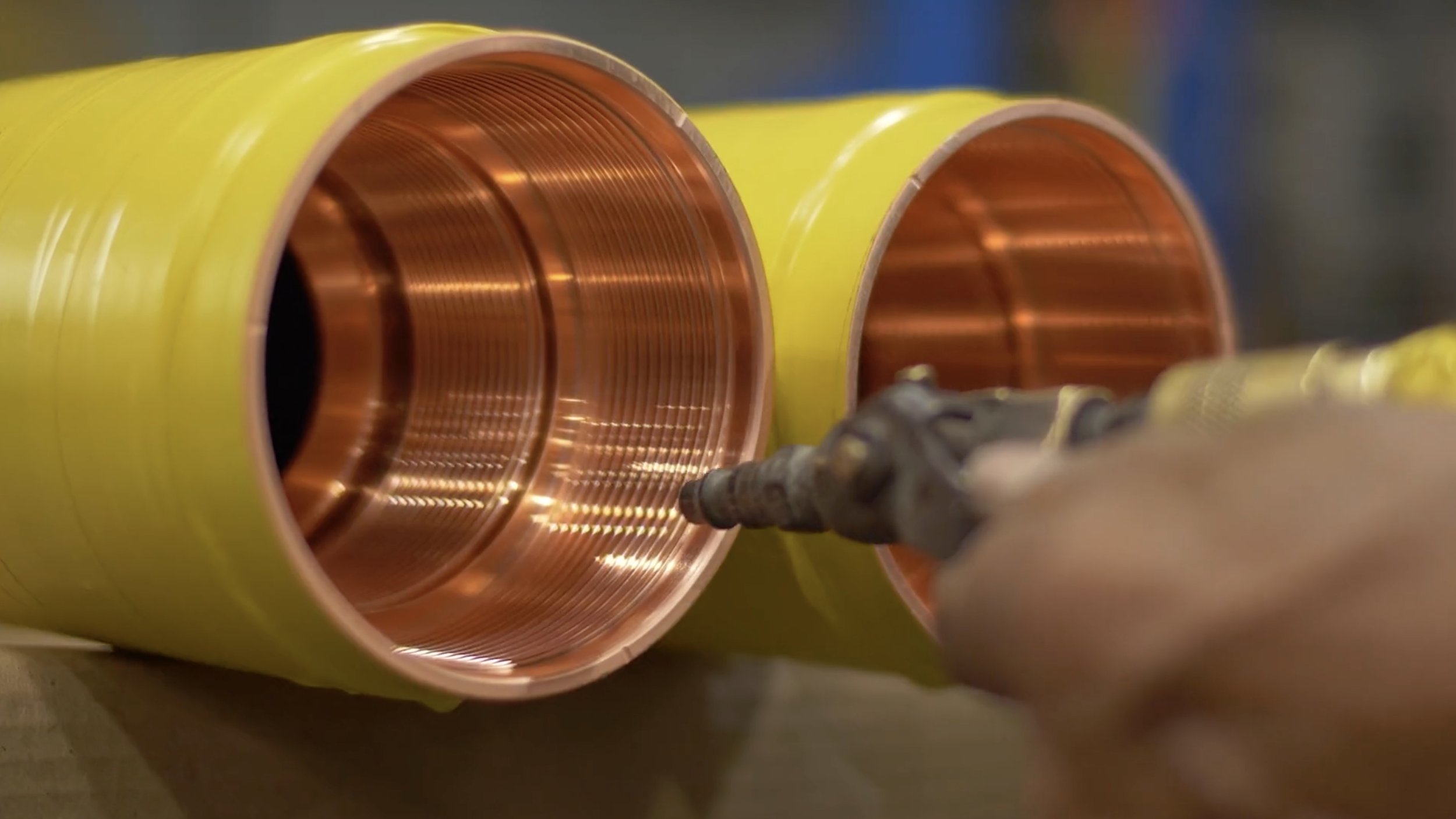

Plating with Copper, Silver, Phosphate, and More

In addition to having the world’s largest bus bar plating operation, our electroplating prowess ensures pipelines, tubing hangers, seat belts, screws, and many other commercial products are protected from corrosion and damage with an attractive finish.

Coatings for Reduced Friction, Better Lubricity, & Superior Hardening

Whether you need a tough finish, fast application, or more reliable pretreatment medium, our premium coatings get the job done.

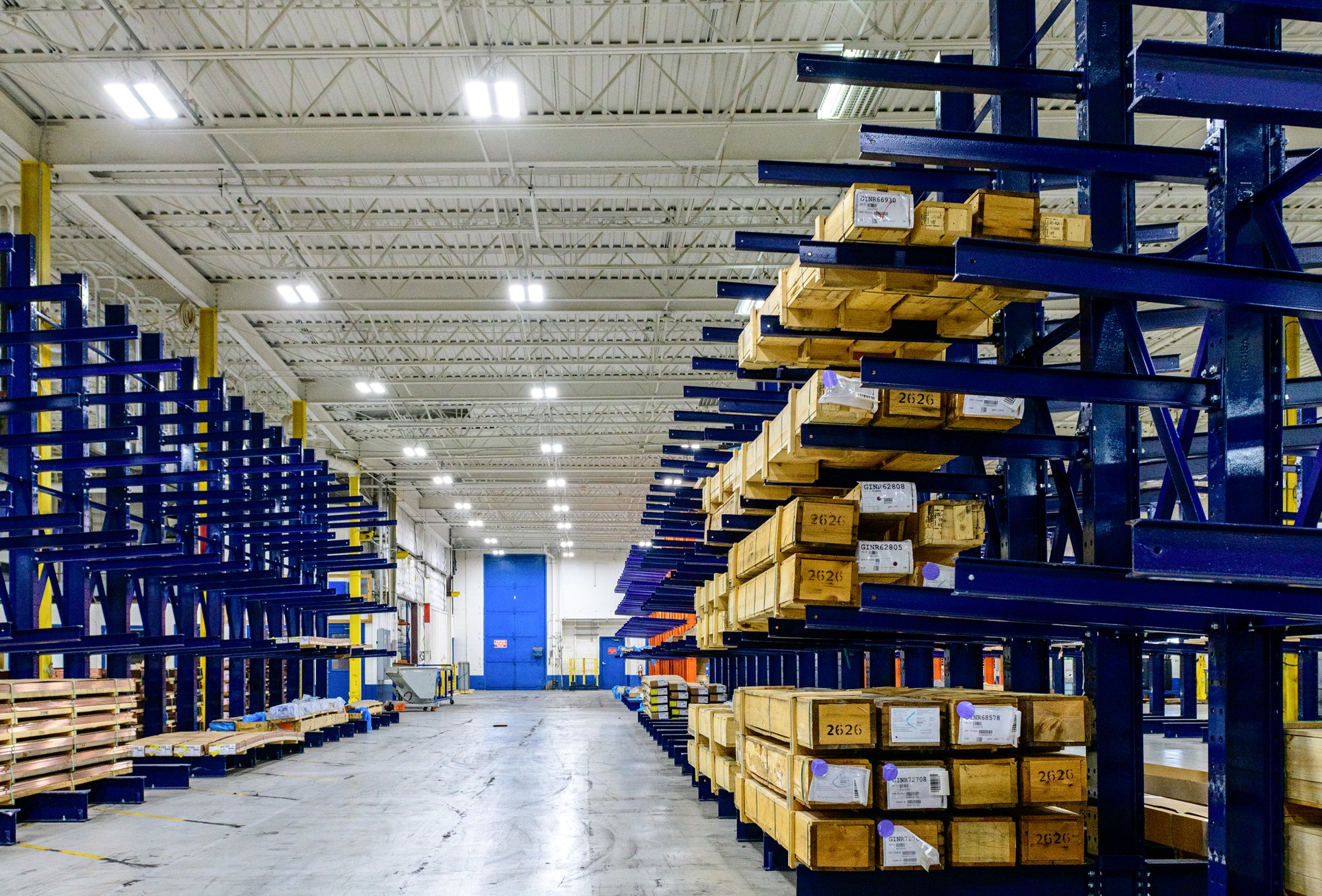

Warehousing Space for Months of Inventory

Reduce your overhead and logistics costs by taking advantage of our ample warehousing area for your raw and finished products.

Full-Service Assembly Capability

Let our experienced team get your products ready for shipment with our in-house assembly, inspection, and packing services.

Serving the Industries That Keep America Moving

Our work is critical for reinforcing components used by four of the most vital sectors of the economy: oil and gas, power generation, automotive and consumer goods.

Oilfield companies entrust us with subsea production manifolds, goat heads, frac sleeves, threaded pipe, and many other components used in both onshore and offshore drilling applications.

With our silver and tin plating on copper and aluminum bus bars, we are a leading service provider for these conductors found in power generation equipment such as switchgear, panel boards, and busways.

And we supply the automotive industry with plating for safety-critical components that can extend longevity and reliability.